GPR Scanning for Risk Mitigation on Existing Structures

3D GPR Plain View

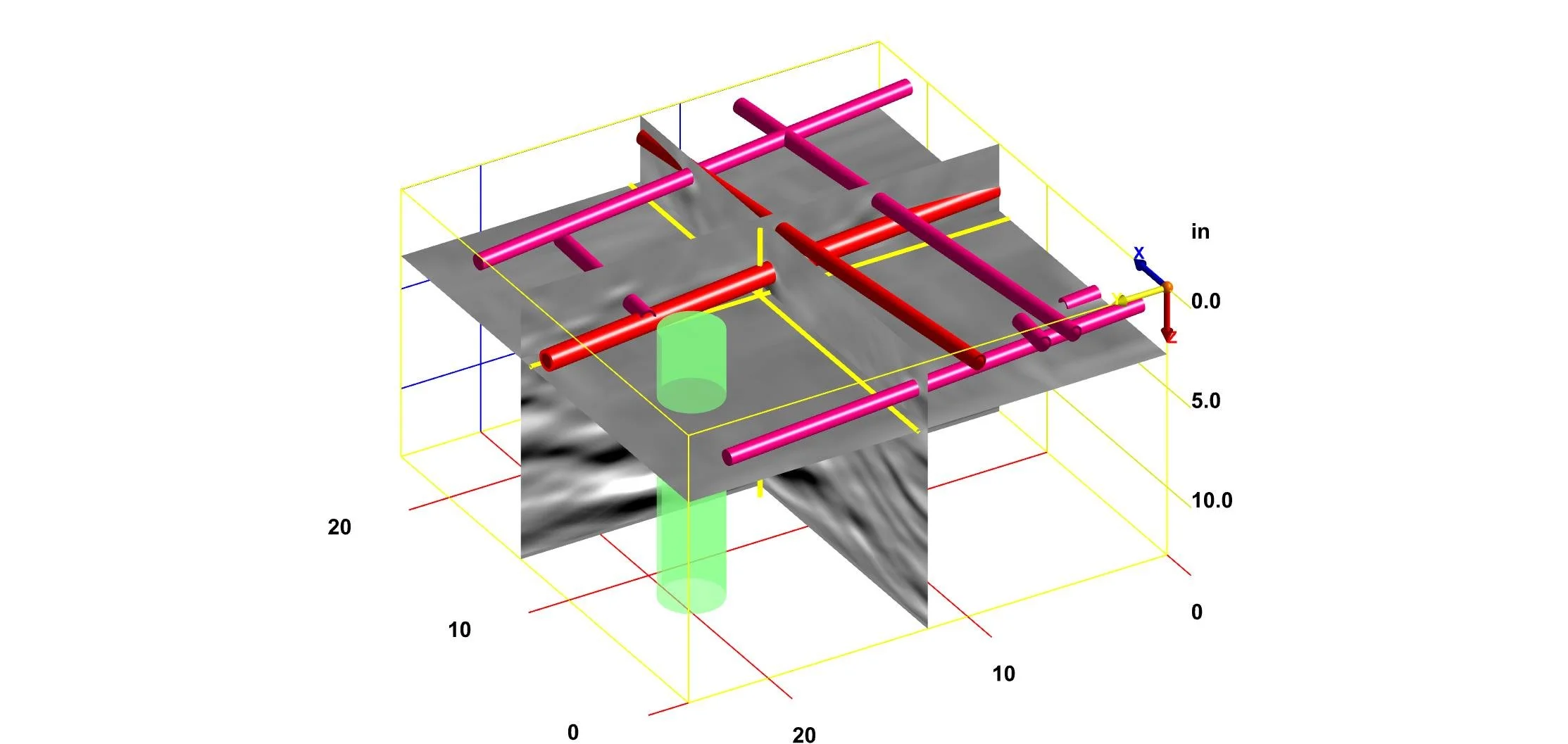

3D Hybrid

GPR is a powerful tool to use to identify and locate unseen objects such as rebar and post tension cables that lay beneath the surface of concrete slabs, beams and walls. This article explains what GPR scanning is, how it can be used to reduce the risk of construction defects and liabilities, and why it should be a part of every construction project.

GPR Work in Progress

Starting from the ground up…

Ground-penetrating radar (or GPR) uses electromagnetic waves to locate objects that are buried underground. In layman's terms, you can think of GPR as a type of x-ray for the earth.

GPR is used to locate metal (such as rebar and post tension cables), highly conductive materials and various voids buried beneath the surface of a parking lot, house foundation, bridge, sidewalk etc. The radar signal propagates in the same manner that it does from a weather satellite image. The radar signal is reflected by the material it encounters and is received at a later time.

The strength of the reflection depends on the type of material and its moisture content. GPR employs pulse-echo techniques, which sends a short burst of energy in a specified direction; that energy bounces off any nearby objects and is returned back to the source for evaluation. Unique patterns can be created to identify different types of materials even when they are underground or covered with dirt or asphalt.

Modern GPR systems have the ability to measure extremely small variations in the reflected signals. This makes it possible for the scanner to create a three-dimensional map of the surrounding area, and to give a measurement of its own position. Thus, this technology allows construction companies to find buried objects and determine whether they are dangerous.

Different frequencies of antennas and shapes of the devices are determined by the location where the scan will take place, as well as the depth of the material scanned and the surface or subsurface you are scanning. GPR devices are used by professionals to locate underground infrastructure like cables, steel reinforcement in concrete, electrical systems and pipes. They are also widely used for production improvement and inspection of cured concrete (for example, areas where cracks or bubbles can occur). This type of technology allows you to locate these objects from the surface, which is very important when you're working on a high-rise building, surface parking lot or parking garage.

If you are repairing a concrete slab, cutting into concrete, excavating soil, coring holes through existing materials or putting heavy loads on a surface it’s important to know what’s hidden. This will help reduce any potential liability.

GPR scanning can be used to detect hidden voids in concrete slabs and beams, subsurface soils, etc. Sometimes these voids are created by settlement, washout and expansive clays. In any case, you need to identify these voids immediately and have them documented as soon as possible. The scan will tell you what the shape and size of the void is so that you can properly address its impact on the safety of your work and your employees.

When you are building a new structure, upgrading or remodeling, especially a high-rise building, you may be asked to scan existing concrete and asphalt structures on the site. When you are surveying existing structures that are built on soil (such as parking lots), you should use GPR scanning to find utilities and other underground infrastructure members that lie beneath the surface. You can then take appropriate actions to determine whether there are concerns in the design and or location of the work you will be performing.

In conclusion, the cost to address and mitigate potential damage or safety concerns is very small compared to the potential loss that may be experienced by blindly cutting, coring, digging or placing loads on unknown subsurface conditions. The time, costs and liability associated with repairing a damaged slab or beam are overwhelming. You don’t want to find yourself in this situation.

In any project, with any material for any purpose, there is always an element of risk. Understanding it and mitigating it is your job as an owner, architect, engineer or contractor, and we hope to reduce the risk for you.

If you have questions about how GPR can be used to help your project please contact us at info@omnivuendt.com.