NDT, Non-Destructive Testing

Concrete Structural and Integrity inspections with UT, UPV, SPV, Impact-Echo.

OminVueNDT’s non-destructive testing services include Pile Integrity Testing (PIT), Impact Echo (IE), and Ultrasonic Pulse Velocity (UPV) to ensure the integrity and quality of various structural components. PIT evaluates the soundness of vertical or inclined piles by measuring the velocity response induced by an impact device, making it ideal for forensic evaluations and quality assurance in new construction. IE assesses the condition and thickness of structural members like slabs, beams and walls by detecting voids, cracks and honeycombs, with the advantage of requiring access to only one side of the structure. UPV identifies and maps internal defects in materials such as concrete, wood and masonry by analyzing compressional waves, offering comprehensive insights into the volume and extent of the damage. Together, these methods provide reliable assessments to ensure the safety and durability of your structures.

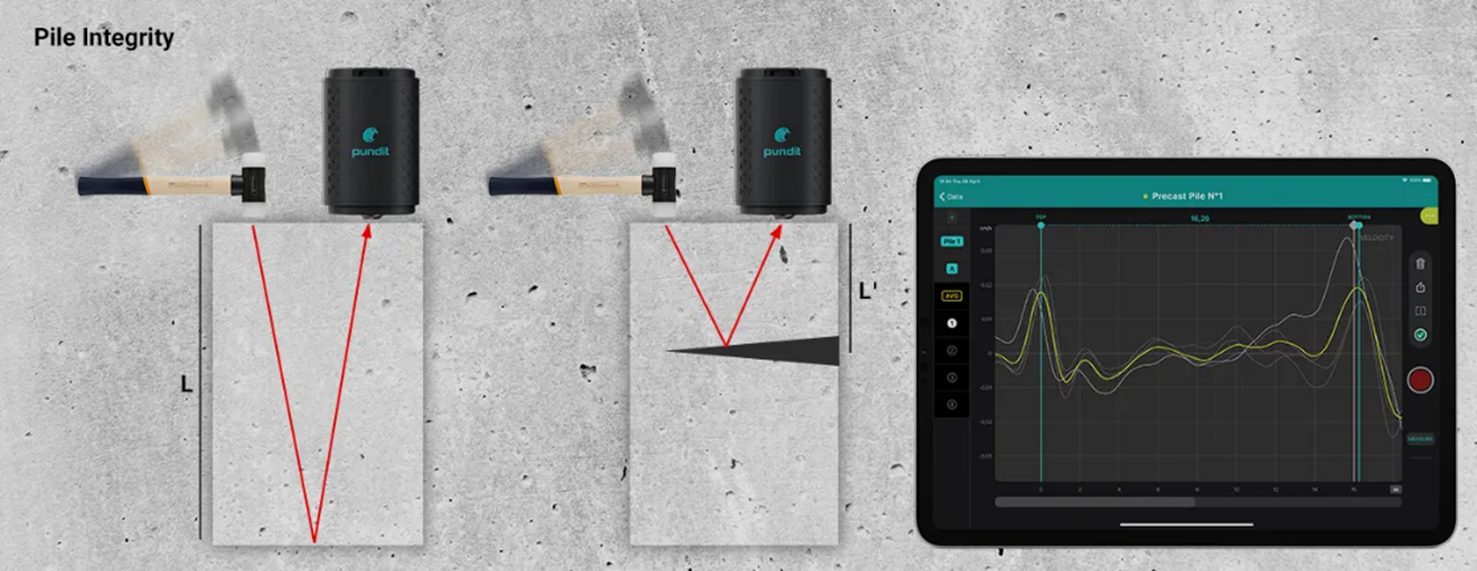

PIT - Pile Integrity Testing

Pile integrity test covers the procedure for determining the integrity of individual vertical or inclined piles by measuring and analyzing the velocity (required) and force (optional) response of the pile induced by an (handheld hammer or other similar type) impact device usually applied axially and perpendicularly to the pile head surface.

Pile integrity test (PIT) is a common non-destructive testing method for the evaluation of pile integrity and/or pile length. Pile integrity test can be used for forensic evaluations on existing piles or quality assurance in the new construction.

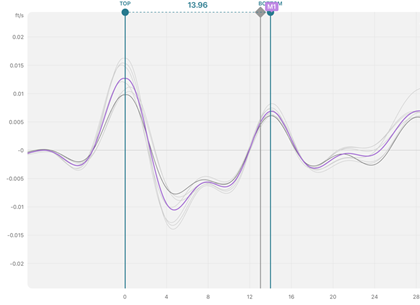

Impact Echo (IE)

Impact Echo (IE) investigations are performed to assess the condition or thickness of slabs, beams, columns, walls, pavements, runways, tunnels, and dams.

The Impact Echo (IE) system is designed to determine the condition and thickness of concrete, wood, stone, and masonry structural members when voids, honeycomb, and/or cracks are suspected. IE investigations can also be performed to predict the strength of early age concrete if the member thickness is known. Lastly, the IE method will provide information on the depth of a flaw or defect, in addition to mapping its lateral location and extent. An advantage of the IE method over the Ultrasonic Pulse Velocity (UPV) method is that only one side of the structure needs to be accessible for testing.

UPV - Ultrasonic Pulse Velocity

The Ultrasonic Pulse Velocity (UPV) systems are designed to identify and map voids, honeycomb, cracks, delamination, and other damage in concrete, wood, masonry, stone, ceramics, and metal materials. UPV tests are also performed to predict strength of early age concrete. The UPV methodology relies on direct arrival of compressional waves.

The test is performed by positioning the source and receiver on either side of the area in question, then the source sends a compressional wave through the region, and the receiver records the full waveform on the other side. The position of the two transducers can be varied such that direct, semi-direct, and indirect tests can be performed, which aids in mapping out the volume of the defect.