Cooling Tower Maintenance Support with NII

Cooling towers are playing an important and critical role at Refineries and Chemical Plants. It is crucial to maintain adequate conditions for safe processes. There are two ways of doing maintenance work. One is scheduled maintenance, and the other one is emergency maintenance. Whether it is a scheduled or emergency situation, the project always involves crane placements.

Heavy parts can be replaced by utilizing heavy cranes onsite. There are several safety hazard protocols that need to be followed prior to crane placement, as well as during the process. One of the first safety hazards is the “UNKNOWN SUBSURFACE HAZARDS” that goes first on the list. That hazard can be recognized by conducting a “Non-intrusive Investigations, NII”.

One of the most effective NII methods is carried out with a Ground Penetrating Radar (aka, GPR) instrument. It is a terrestrial geophysical survey method that is typically used to find unknown origin subsurface obstructions or faults. The data collection process is swift and accurate. Even the pre-data assessment can be performed onsite, thus providing preliminary information to clients so they can start mitigating the potential hazards that were found after the investigation.

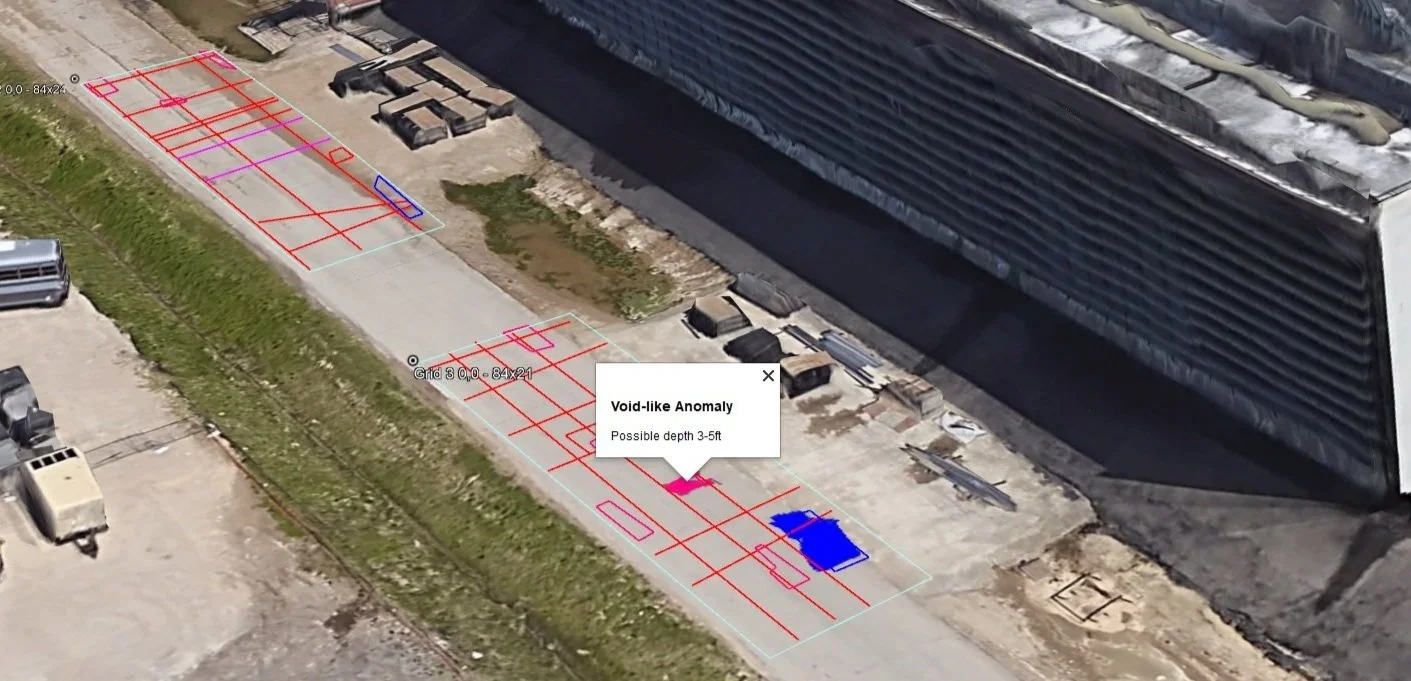

The deliverable of this type of Subsurface Condition Assessment is a scaled CAD map and a GIS database that is 100% interchangeable and portable at the same time. Images below are the GIS map indicating subsurface anomalies that are recommended to avoid setting a crane on top of it (See PINK and BLUE polygons).

OmniVueNDT specializes in performing such assessments with the highest level of accuracy. Our dedicated industrial crew is highly trained on the work process as well as safety training to follow safe work practices inside various types of hazardous environments.